Last Updated January 26, 2025

Summary

This 463-bed acute care hospital in Toms River, New Jersey, faced high infection rates, with compromised sterile trays suspected as the cause. Surgical Directions first provided recommendations to improve the Sterile Processing (SP) unit, but no progress was made due to leadership turnover. Subsequently, the hospital hired Surgical Directions to implement the changes. Surgical Directions deployed a team of experts, conducted a thorough process analysis, and recommended best-practice improvements, including staff training, workflow optimization, and equipment upgrades. As a result, instrument turnaround improved, lost instruments decreased, and infection rates began to drop. Pleased with the progress, Barnabas Health extended the overhaul to all perioperative services.

Situation

Sterile Processing Challenges

Barnabas Health was experiencing a higher-than-typical infection rate of unknown etiology. Leadership suspected that inefficiencies in core processes had something to do with it. In addition, feedback from surgeons and clinicians revealed that sterile trays were being compromised. The community medical center contacted Surgical Directions to assess and improve their perioperative services.

Strategy

Surgical Directions provided a detailed report to the leadership of Barnabas Health, who decided to implement the recommendations using internal staff.

Nearly a year after providing the report, we followed up with Barnabas Health to check on their progress. In the interim, there had been turnover among senior leadership and no progress made on the report recommendations. Determined to make the change necessary for long-term improvements in service delivery, the hospital leaders hired Surgical Directions to implement the improvements to the Sterile Processing (SP) department that were previously identified.

Provide interim guidance and training.

Surgical Directions recruited an experienced SP Nurse Manager to immediately address the organization’s concerns.

Conduct an in-depth analysis of current processes

Surgical Directions deployed a support team of SP and operating room (OR) experts to observe, assess and provide additional support as they worked with the health center to fix the root cause of their perioperative infections. The team was composed of perioperative nurses, experienced nursing executives, SME consultants, leadership professionals in key work areas and hospital administrators. They observed how product from SP arrived at the OR, how it was handled and how it was transported back to SP. Sterilization and decontamination processes were observed, as were work requests that required the transport and servicing of instruments and patient care equipment from hospital floors and units.

Recommend best-practice standards and workflow improvements

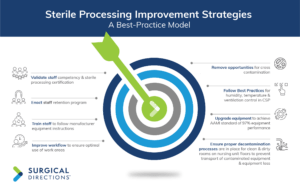

After observation, the team outlined the current state of SP, identified gaps between current and best practices, and recommended implementation strategies to close those gaps, including:

- Validate staff competency and sterile processing certification.

- Enact staff retention program.

- Train staff to follow manufacturer equipment instructions.

- Improve workflow to ensure optimal use of work areas.

- Remove opportunities for cross contamination.

- Upgrade equipment to achieve AAMI standard of 97% equipment performance.

- Follow best practices for humidity, temperature and ventilation control in CSP.

- Ensure proper decontamination processes are in place for clean and dirty rooms on nursing unit floors to prevent transport of contaminated equipment and equipment loss.

Results

Since the overhaul of SP, instrument turnaround and tracking have improved, the number of lost instruments has reduced, and the infection rate is dropping in many of their surgical specialties. The workflow and processes were changed to remove the possibility of trays being compromised. Pleased with the early results within SP, Barnabas Health has asked Surgical Directions to begin the same process within all areas of perioperative services.

Stay tuned for from the results of this comprehensive perioperative transformation project, which will be led by hospital leadership and facilitated by Surgical Directions.